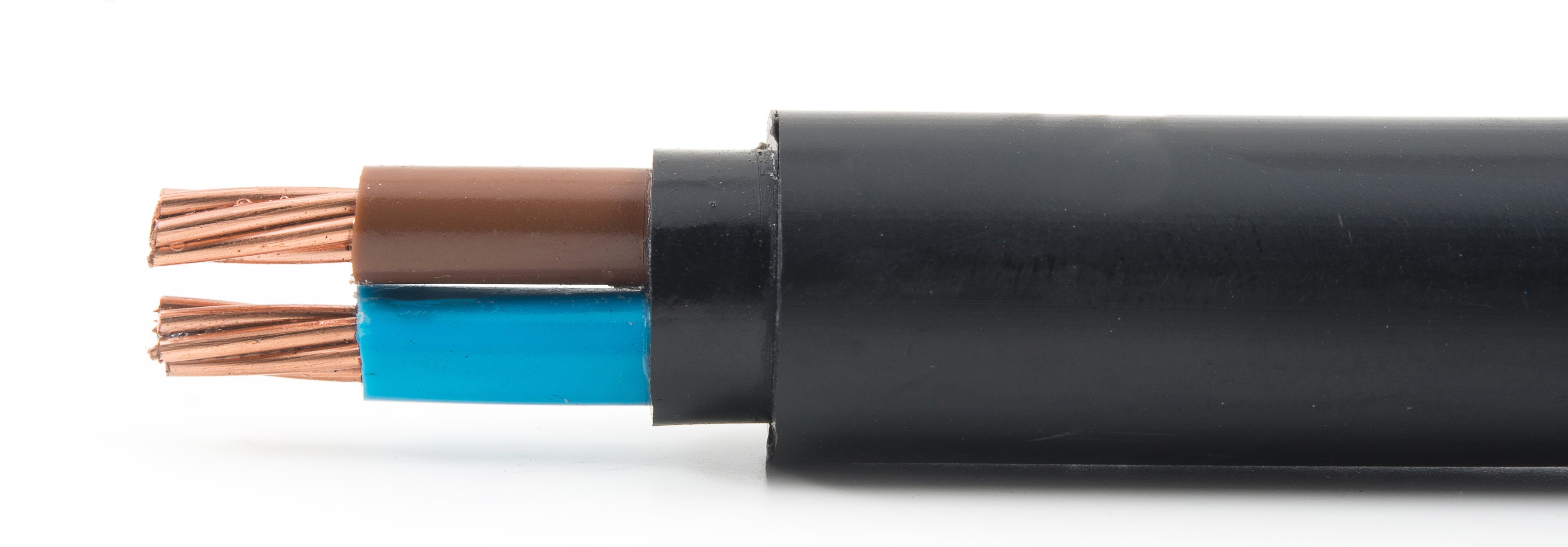

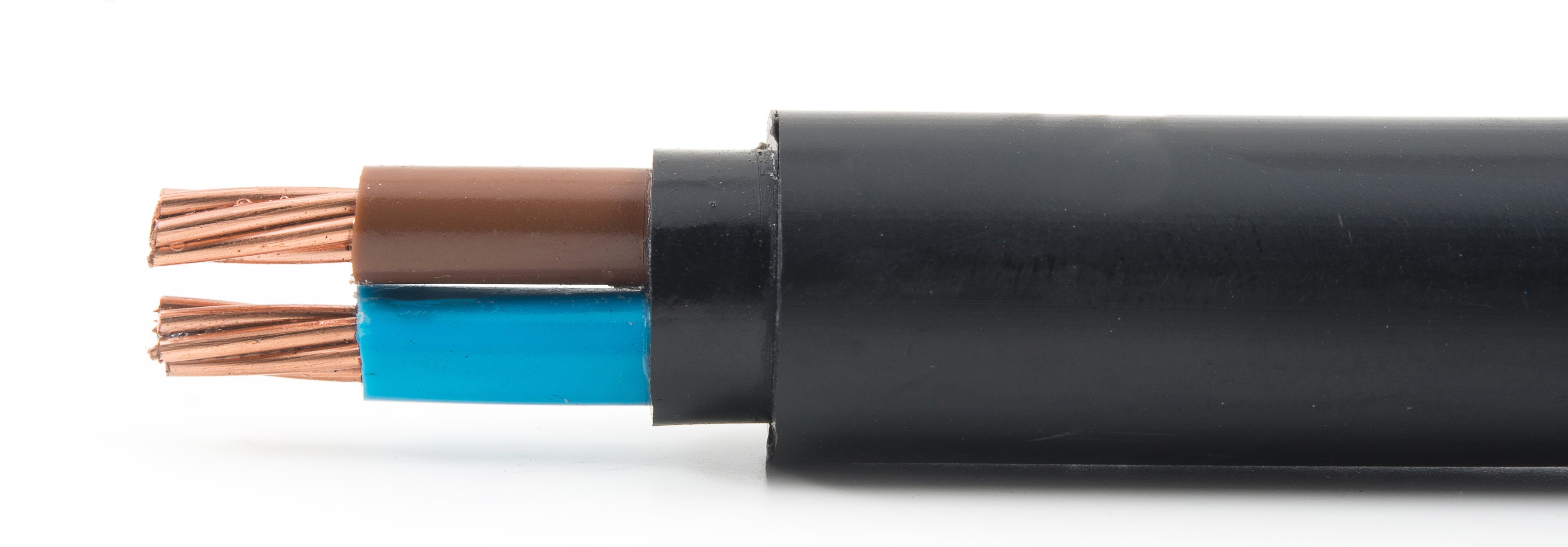

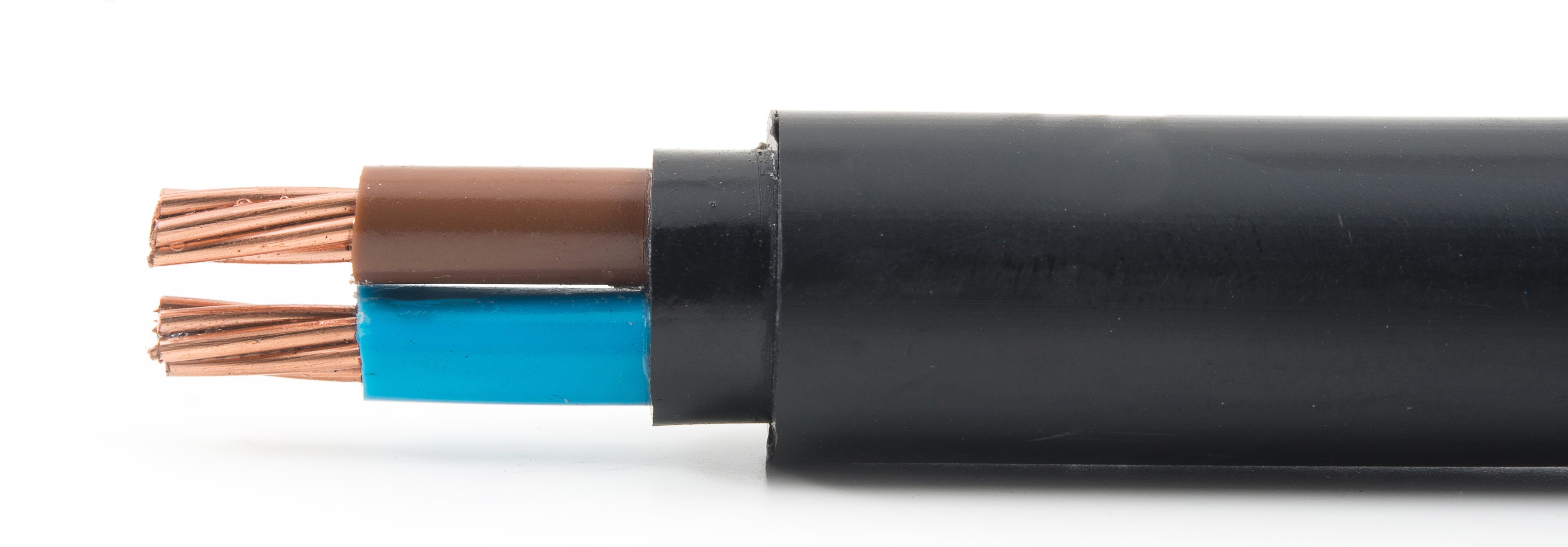

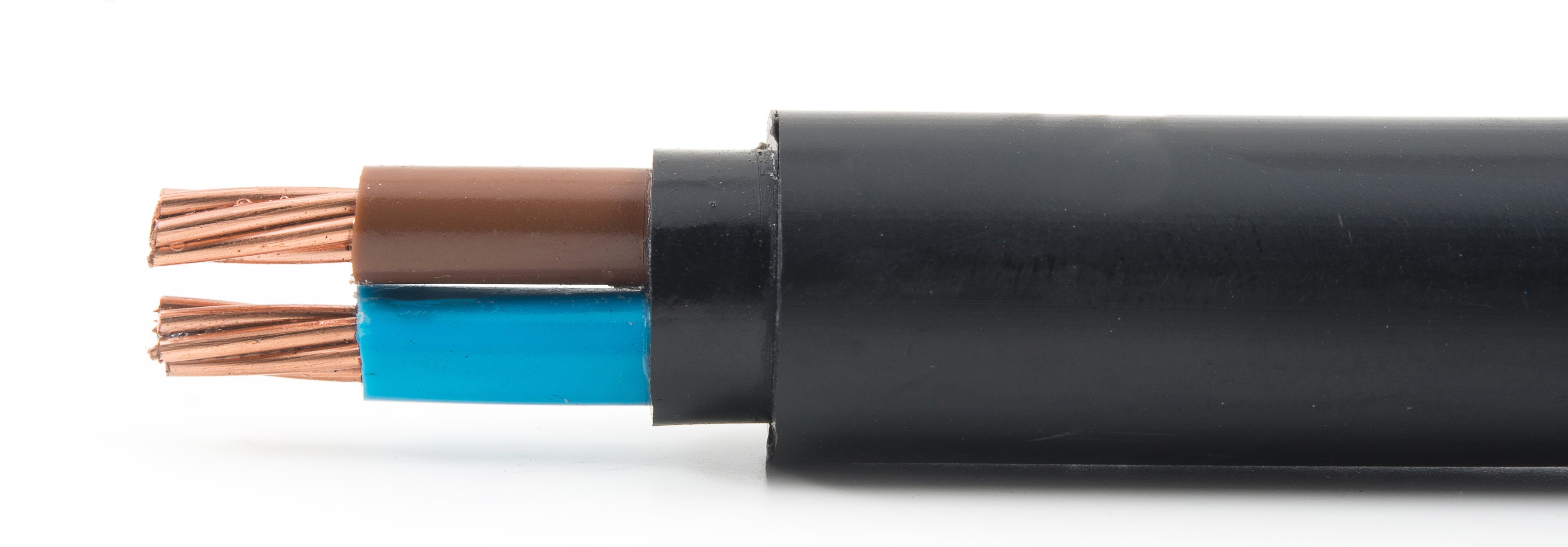

Linkflex HF range is focused on bulding applications for low and medium voltage applications. With different grades, Hiflex is able to cover standard 300/500V basic levels up to the highest CPR classes and energy applications.

Based on polyolefin matrix, the Linkflex HF series complies with IEC60754-2 standard for low acidity emissions. Behavior during fire exposure has been optimized to allow cables to meet EN 50575 standard classes from Eca up to B2ca with associated features such as low droplet generation.

Mechanical, chemical resistance and climatic characteristics has been optimized to allow high level of flexibility and easiness of use for final users.

A particular care has been taken to optimize the key characteristics for cable processing, to make sure that the total cost for cable manufacturer remains efficient and under control.

The latest compounding processing techniques has been chosen to make sure that product stability and quality are at optimum levels.

In addition, BENVIC's created a dedicated enginnering team with cable compound designers that provides the support to extend and adapt the properties of the Linkflex HF range for specific customer needs.

The Linkflex HF series complements BENVIC's expertise in PVC compounds and reaffirms the company's expertise in productions for the building, construction, electrical and cable industries.all cables manufacturers, and being a long term partner for cable polymers.

Deployment of high speed internet and 5G wireless technology call for range of cable able to meet the application specific requirements and able to offer long life service. Linkflex HF grades are dedicated for based on CPR rated thin layer case.

Benvic compounding know how is a great advantage regarding the formulation of cable where specific features, mission critical, need to be ensured without compromises. Dedicated engineering teams for cable compounds can sustain customer cases for marine, industrial, automotive and transportation applications.

Linkflex HF is using polyolefin matrix which allows low acidity smokes to meet the latest safety requirements.

Linkflex HF does not simply offer compliance with market regulations. Successful cable manufacturers must also demonstrate value-for-money products. This can only happen by focusing on an optimum performance in plastics processing and by minimizing and removing non-quality and non-efficiency costs. Benvic has taken particular care to produce the new Linkflex range at optimum cost.

.

|

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS002 |

>10 |

>150 |

38 |

49 |

-40/90* |

IEC Sheatig 1kV Cable |

HFS002-G |

>10 |

>125 |

38 |

42 |

-40/90* |

BS Sheating 1kV cables |

HFS003 |

>10 |

>150 |

39 |

48 |

-40/90* |

CPR Sheating 1kV Cable |

HFS009 |

>12.5 |

>300 |

- |

- |

-40/90* |

Cables for energy distribution (LV UTILIES) |

HFM001 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV Cable |

|

|

|

|

|

|

|

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

Applicable Standard |

HFI009 |

1.57 |

>10 |

>150 |

40 |

45 |

-25/70 |

LV Insulation H05Z1 & H07Z1 cables Mass insulation (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI011 |

1.54 |

>10 |

>150 |

35 |

48 |

-25/70 |

Insulation H05Z1 & H07Z1 cables Skin layer (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI012 |

1.49 |

>10 |

>150 |

34 |

52 |

-25/70 |

Thermoplastic Insulation for Z1Z1, Z1C4Z1 cables (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI014 |

1.57 |

>10 |

>125 |

37 |

51 |

-25/70 |

CPR Insulation H05Z1 & H07Z1 cables Mass insulation |

EN5363-7 TI7 |

HFI018 |

1.59 |

>10 |

>125 |

41 |

51 |

-25/70 |

Insulation for 500V & 750V cables. CPR (B2ca) |

EN5363-7 TI7

|

HFM001 |

1.61 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV cable |

EN5363-7 TI6 EN5363-7 TI7 |

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

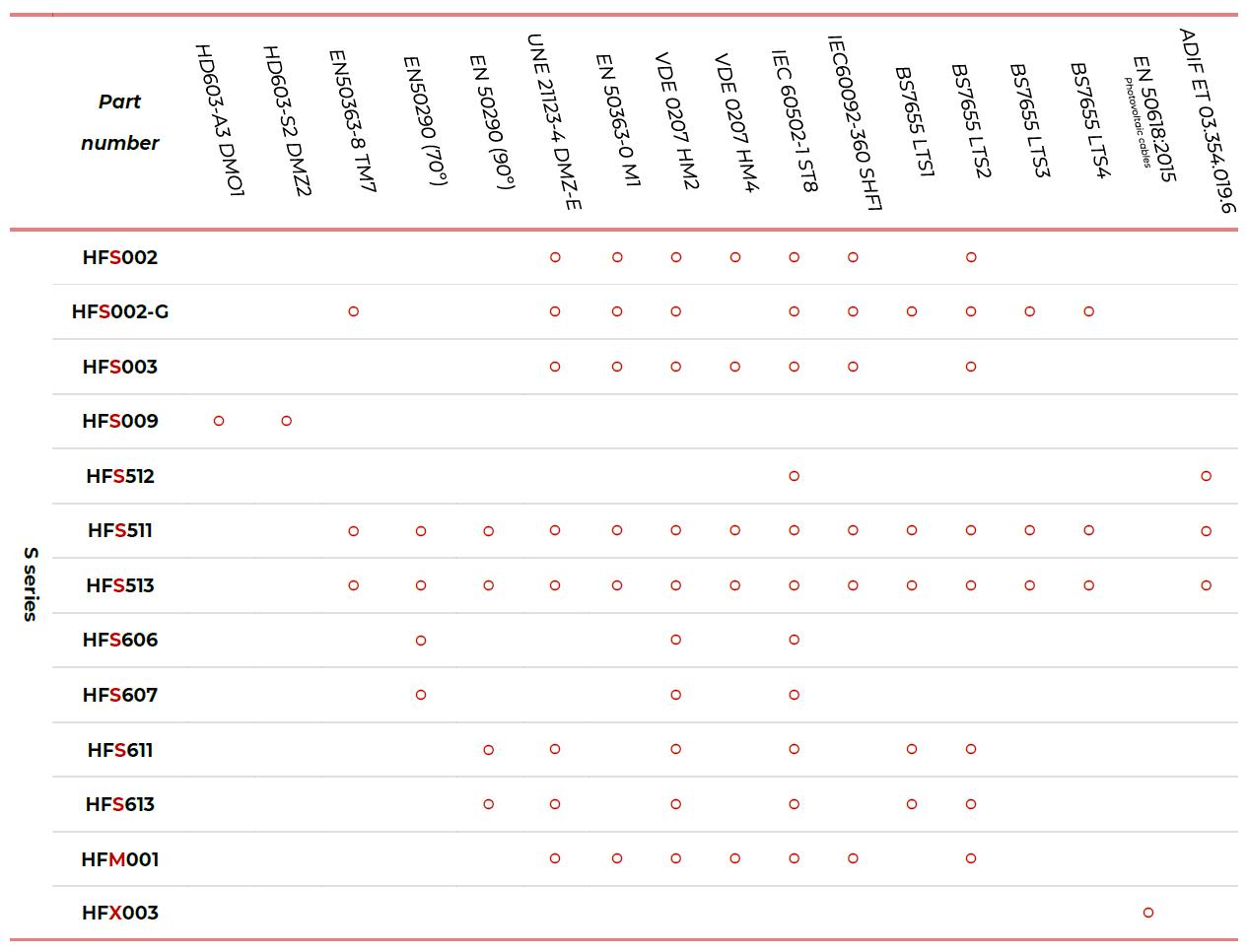

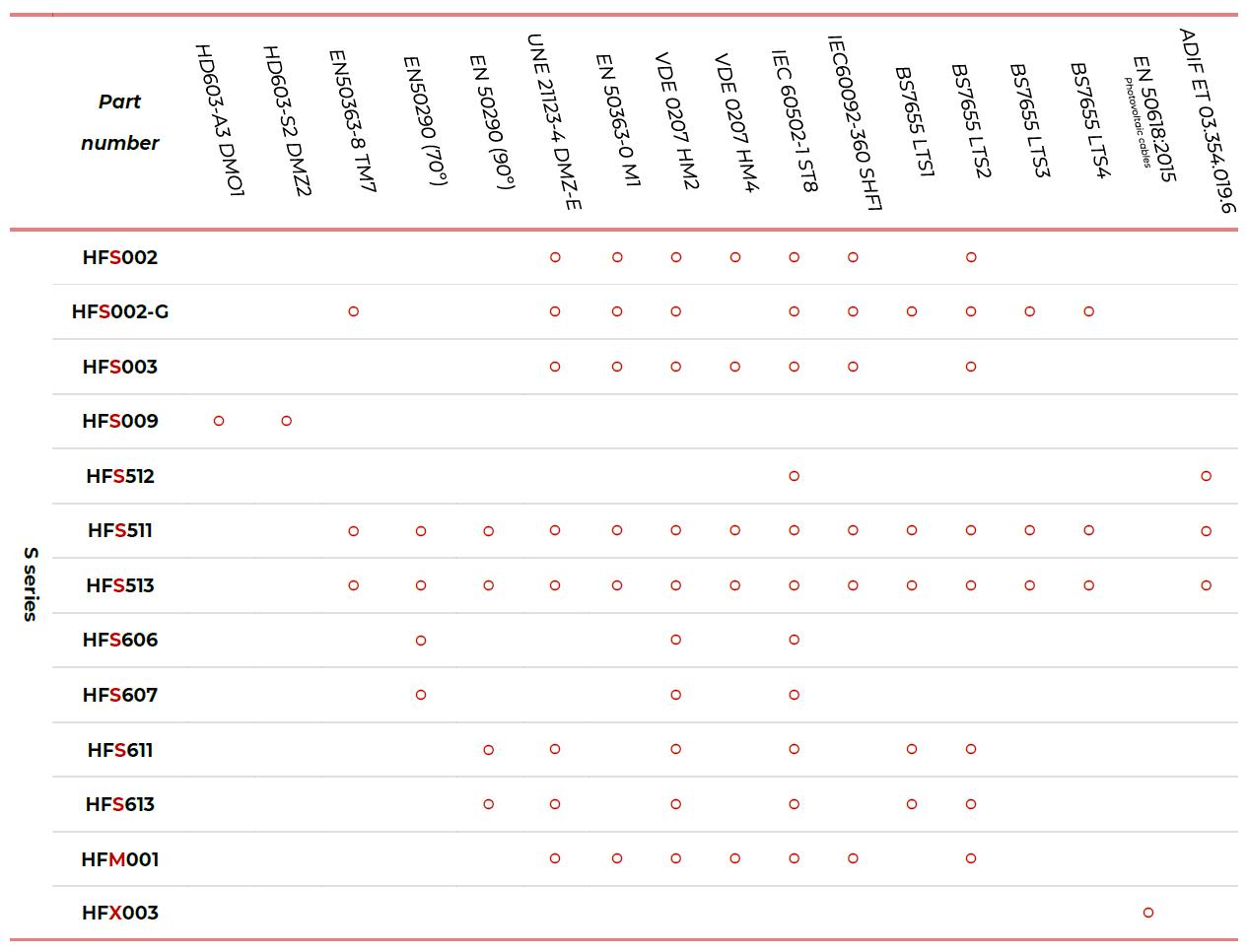

Building residential |

Public building |

Datacom |

Fiber Optic |

Energy |

Photovoltaic |

Utilities Industrial |

HFS002 |

O |

O |

O |

|

|

|

O |

HFS002-G |

O |

O |

O |

|

|

|

O |

HFS003 |

O |

O |

O |

|

|

|

|

HFS009 |

|

|

|

|

O |

|

|

HFS512 |

O |

O |

O |

|

|

|

|

HFS511 |

|

|

|

|

|

|

O |

HFS513 |

|

|

|

|

|

|

O |

HFS606 |

|

|

O |

O |

|

|

|

HFS607 |

|

|

O |

O |

|

|

|

HFS611 |

|

|

|

O |

|

|

|

HFS613 |

|

|

O |

O |

|

|

|

HFM001 |

O |

O |

O |

O |

O |

O |

O |

HFX003 |

|

|

|

|

|

O |

|

HFI009 |

O |

O |

|

|

|

|

|

HFI011 |

O |

O |

|

|

|

|

O |

HFI012 |

O |

O |

|

|

O |

|

|

HFI014 |

O |

O |

|

|

|

|

|

HFI018 |

O |

O |

|

|

|

|

|

HFM001 |

O |

|

|

|

O |

|

O |

Compliance up to the indicated CPR euroclass associated to right cable design. (1)

Formulation optimization to meet EN 50575 for a use according the latest regulations.

Versions designed to meet the highest requirements in terms of temperature for high reliability usage.

Linkflex HF contributes to low smoke emission cable design as per IEC60754.

Resistance to abrasion makes Linkflex HF an excellent choice for the most demanding cable installation conditions such as conduit, cable trays, stringent bends …

Linkflex HF is offering an excellent flexibility to ensure performance and easiness during network installations.

Crosslinked grades for improving servicing temperature and mechanical properties for a suitable usage in harsh conditions

Resistance to solvents and other chemical resistance against hydrocarbons and oils.

(*) Valid for XLPE insulationcable.

Data sheets on request.

Linkflex HF is particularly adapted for sheathing the whole range of voltage requirement for energy cables, from low to extra high voltage.

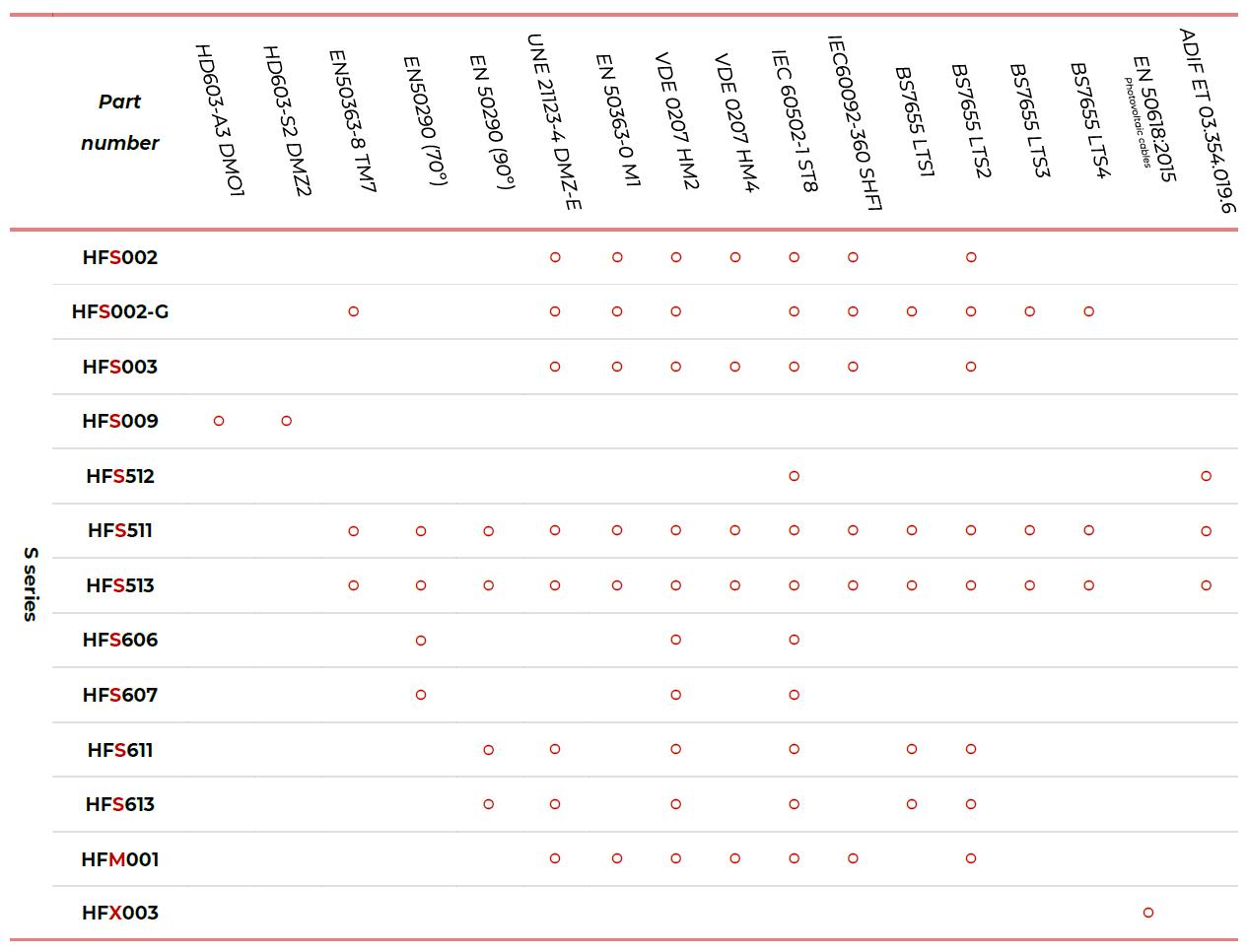

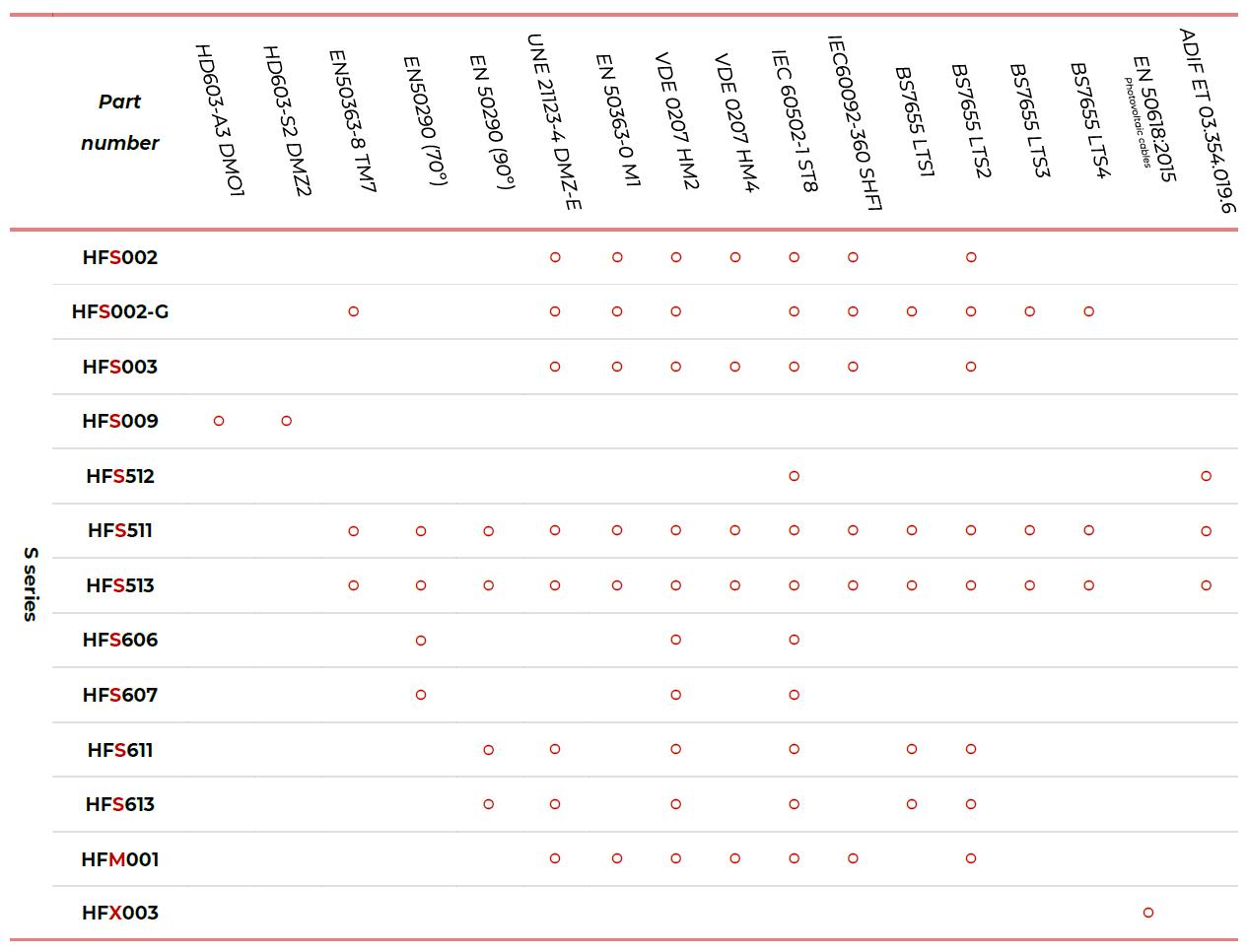

O Product compatibile with the application

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS606 |

1.54 |

>10 |

>150 |

27 |

46 |

-25/90 |

DataCom, FO sheating (Eca) |

HFS607 |

1.51 |

>10 |

>125 |

34 |

43 |

-25/90 |

DataCom, FO sheating. Enhancd Fire Performance |

HFS611 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

FTTH ESCR |

HFS613 |

1.58 |

>10 |

>125 |

38 |

44 |

-40/90* |

FTTH ESCR enhanced fire |

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFX003 |

1.49 |

>10 |

>150 |

- |

40 |

-25/90 |

Sheating moisture crosslinkable compound for photovolatic cables |

|

|

|

|

|

|

|

|

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS512 |

1.58 |

>10 |

>150 |

38 |

48 |

-40/90* |

Sheating compound for armored Railway Network |

HFS511 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

Desert grade LSOH armored cables |

HFS513 |

1.58 |

>10 |

>150 |

37 |

52 |

-40/90* |

CPR Desert grade LSOH armored cables |

Linkflex HF range is focused on bulding applications for low and medium voltage applications. With different grades, Hiflex is able to cover standard 300/500V basic levels up to the highest CPR classes and energy applications.

Based on polyolefin matrix, the Linkflex HF series complies with IEC60754-2 standard for low acidity emissions. Behavior during fire exposure has been optimized to allow cables to meet EN 50575 standard classes from Eca up to B2ca with associated features such as low droplet generation.

Mechanical, chemical resistance and climatic characteristics has been optimized to allow high level of flexibility and easiness of use for final users.

A particular care has been taken to optimize the key characteristics for cable processing, to make sure that the total cost for cable manufacturer remains efficient and under control.

The latest compounding processing techniques has been chosen to make sure that product stability and quality are at optimum levels.

In addition, BENVIC's created a dedicated enginnering team with cable compound designers that provides the support to extend and adapt the properties of the Linkflex HF range for specific customer needs.

The Linkflex HF series complements BENVIC's expertise in PVC compounds and reaffirms the company's expertise in productions for the building, construction, electrical and cable industries.all cables manufacturers, and being a long term partner for cable polymers.

Deployment of high speed internet and 5G wireless technology call for range of cable able to meet the application specific requirements and able to offer long life service. Linkflex HF grades are dedicated for based on CPR rated thin layer case.

Benvic compounding know how is a great advantage regarding the formulation of cable where specific features, mission critical, need to be ensured without compromises. Dedicated engineering teams for cable compounds can sustain customer cases for marine, industrial, automotive and transportation applications.

Linkflex HF is using polyolefin matrix which allows low acidity smokes to meet the latest safety requirements.

Linkflex HF does not simply offer compliance with market regulations. Successful cable manufacturers must also demonstrate value-for-money products. This can only happen by focusing on an optimum performance in plastics processing and by minimizing and removing non-quality and non-efficiency costs. Benvic has taken particular care to produce the new Linkflex range at optimum cost.

.

|

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS002 |

>10 |

>150 |

38 |

49 |

-40/90* |

IEC Sheatig 1kV Cable |

HFS002-G |

>10 |

>125 |

38 |

42 |

-40/90* |

BS Sheating 1kV cables |

HFS003 |

>10 |

>150 |

39 |

48 |

-40/90* |

CPR Sheating 1kV Cable |

HFS009 |

>12.5 |

>300 |

- |

- |

-40/90* |

Cables for energy distribution (LV UTILIES) |

HFM001 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV Cable |

|

|

|

|

|

|

|

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

Applicable Standard |

HFI009 |

1.57 |

>10 |

>150 |

40 |

45 |

-25/70 |

LV Insulation H05Z1 & H07Z1 cables Mass insulation (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI011 |

1.54 |

>10 |

>150 |

35 |

48 |

-25/70 |

Insulation H05Z1 & H07Z1 cables Skin layer (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI012 |

1.49 |

>10 |

>150 |

34 |

52 |

-25/70 |

Thermoplastic Insulation for Z1Z1, Z1C4Z1 cables (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI014 |

1.57 |

>10 |

>125 |

37 |

51 |

-25/70 |

CPR Insulation H05Z1 & H07Z1 cables Mass insulation |

EN5363-7 TI7 |

HFI018 |

1.59 |

>10 |

>125 |

41 |

51 |

-25/70 |

Insulation for 500V & 750V cables. CPR (B2ca) |

EN5363-7 TI7

|

HFM001 |

1.61 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV cable |

EN5363-7 TI6 EN5363-7 TI7 |

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Building residential |

Public building |

Datacom |

Fiber Optic |

Energy |

Photovoltaic |

Utilities Industrial |

HFS002 |

O |

O |

O |

|

|

|

O |

HFS002-G |

O |

O |

O |

|

|

|

O |

HFS003 |

O |

O |

O |

|

|

|

|

HFS009 |

|

|

|

|

O |

|

|

HFS512 |

O |

O |

O |

|

|

|

|

HFS511 |

|

|

|

|

|

|

O |

HFS513 |

|

|

|

|

|

|

O |

HFS606 |

|

|

O |

O |

|

|

|

HFS607 |

|

|

O |

O |

|

|

|

HFS611 |

|

|

|

O |

|

|

|

HFS613 |

|

|

O |

O |

|

|

|

HFM001 |

O |

O |

O |

O |

O |

O |

O |

HFX003 |

|

|

|

|

|

O |

|

HFI009 |

O |

O |

|

|

|

|

|

HFI011 |

O |

O |

|

|

|

|

O |

HFI012 |

O |

O |

|

|

O |

|

|

HFI014 |

O |

O |

|

|

|

|

|

HFI018 |

O |

O |

|

|

|

|

|

HFM001 |

O |

|

|

|

O |

|

O |

Compliance up to the indicated CPR euroclass associated to right cable design. (1)

Formulation optimization to meet EN 50575 for a use according the latest regulations.

Versions designed to meet the highest requirements in terms of temperature for high reliability usage.

Linkflex HF contributes to low smoke emission cable design as per IEC60754.

Resistance to abrasion makes Linkflex HF an excellent choice for the most demanding cable installation conditions such as conduit, cable trays, stringent bends …

Linkflex HF is offering an excellent flexibility to ensure performance and easiness during network installations.

Crosslinked grades for improving servicing temperature and mechanical properties for a suitable usage in harsh conditions

Resistance to solvents and other chemical resistance against hydrocarbons and oils.

(*) Valid for XLPE insulationcable.

Data sheets on request.

Linkflex HF is particularly adapted for sheathing the whole range of voltage requirement for energy cables, from low to extra high voltage.

O Product compatibile with the application

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS606 |

1.54 |

>10 |

>150 |

27 |

46 |

-25/90 |

DataCom, FO sheating (Eca) |

HFS607 |

1.51 |

>10 |

>125 |

34 |

43 |

-25/90 |

DataCom, FO sheating. Enhancd Fire Performance |

HFS611 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

FTTH ESCR |

HFS613 |

1.58 |

>10 |

>125 |

38 |

44 |

-40/90* |

FTTH ESCR enhanced fire |

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFX003 |

1.49 |

>10 |

>150 |

- |

40 |

-25/90 |

Sheating moisture crosslinkable compound for photovolatic cables |

|

|

|

|

|

|

|

|

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS512 |

1.58 |

>10 |

>150 |

38 |

48 |

-40/90* |

Sheating compound for armored Railway Network |

HFS511 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

Desert grade LSOH armored cables |

HFS513 |

1.58 |

>10 |

>150 |

37 |

52 |

-40/90* |

CPR Desert grade LSOH armored cables |

Linkflex HF range is focused on bulding applications for low and medium voltage applications. With different grades, Hiflex is able to cover standard 300/500V basic levels up to the highest CPR classes and energy applications.

Based on polyolefin matrix, the Linkflex HF series complies with IEC60754-2 standard for low acidity emissions. Behavior during fire exposure has been optimized to allow cables to meet EN 50575 standard classes from Eca up to B2ca with associated features such as low droplet generation.

Mechanical, chemical resistance and climatic characteristics has been optimized to allow high level of flexibility and easiness of use for final users.

A particular care has been taken to optimize the key characteristics for cable processing, to make sure that the total cost for cable manufacturer remains efficient and under control.

The latest compounding processing techniques has been chosen to make sure that product stability and quality are at optimum levels.

In addition, BENVIC's created a dedicated enginnering team with cable compound designers that provides the support to extend and adapt the properties of the Linkflex HF range for specific customer needs.

The Linkflex HF series complements BENVIC's expertise in PVC compounds and reaffirms the company's expertise in productions for the building, construction, electrical and cable industries.all cables manufacturers, and being a long term partner for cable polymers.

Deployment of high speed internet and 5G wireless technology call for range of cable able to meet the application specific requirements and able to offer long life service. Linkflex HF grades are dedicated for based on CPR rated thin layer case.

Benvic compounding know how is a great advantage regarding the formulation of cable where specific features, mission critical, need to be ensured without compromises. Dedicated engineering teams for cable compounds can sustain customer cases for marine, industrial, automotive and transportation applications.

Linkflex HF is using polyolefin matrix which allows low acidity smokes to meet the latest safety requirements.

Linkflex HF does not simply offer compliance with market regulations. Successful cable manufacturers must also demonstrate value-for-money products. This can only happen by focusing on an optimum performance in plastics processing and by minimizing and removing non-quality and non-efficiency costs. Benvic has taken particular care to produce the new Linkflex range at optimum cost.

.

|

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS002 |

>10 |

>150 |

38 |

49 |

-40/90* |

IEC Sheatig 1kV Cable |

HFS002-G |

>10 |

>125 |

38 |

42 |

-40/90* |

BS Sheating 1kV cables |

HFS003 |

>10 |

>150 |

39 |

48 |

-40/90* |

CPR Sheating 1kV Cable |

HFS009 |

>12.5 |

>300 |

- |

- |

-40/90* |

Cables for energy distribution (LV UTILIES) |

HFM001 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV Cable |

|

|

|

|

|

|

|

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

Applicable Standard |

HFI009 |

1.57 |

>10 |

>150 |

40 |

45 |

-25/70 |

LV Insulation H05Z1 & H07Z1 cables Mass insulation (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI011 |

1.54 |

>10 |

>150 |

35 |

48 |

-25/70 |

Insulation H05Z1 & H07Z1 cables Skin layer (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI012 |

1.49 |

>10 |

>150 |

34 |

52 |

-25/70 |

Thermoplastic Insulation for Z1Z1, Z1C4Z1 cables (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI014 |

1.57 |

>10 |

>125 |

37 |

51 |

-25/70 |

CPR Insulation H05Z1 & H07Z1 cables Mass insulation |

EN5363-7 TI7 |

HFI018 |

1.59 |

>10 |

>125 |

41 |

51 |

-25/70 |

Insulation for 500V & 750V cables. CPR (B2ca) |

EN5363-7 TI7

|

HFM001 |

1.61 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV cable |

EN5363-7 TI6 EN5363-7 TI7 |

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Building residential |

Public building |

Datacom |

Fiber Optic |

Energy |

Photovoltaic |

Utilities Industrial |

HFS002 |

O |

O |

O |

|

|

|

O |

HFS002-G |

O |

O |

O |

|

|

|

O |

HFS003 |

O |

O |

O |

|

|

|

|

HFS009 |

|

|

|

|

O |

|

|

HFS512 |

O |

O |

O |

|

|

|

|

HFS511 |

|

|

|

|

|

|

O |

HFS513 |

|

|

|

|

|

|

O |

HFS606 |

|

|

O |

O |

|

|

|

HFS607 |

|

|

O |

O |

|

|

|

HFS611 |

|

|

|

O |

|

|

|

HFS613 |

|

|

O |

O |

|

|

|

HFM001 |

O |

O |

O |

O |

O |

O |

O |

HFX003 |

|

|

|

|

|

O |

|

HFI009 |

O |

O |

|

|

|

|

|

HFI011 |

O |

O |

|

|

|

|

O |

HFI012 |

O |

O |

|

|

O |

|

|

HFI014 |

O |

O |

|

|

|

|

|

HFI018 |

O |

O |

|

|

|

|

|

HFM001 |

O |

|

|

|

O |

|

O |

Compliance up to the indicated CPR euroclass associated to right cable design. (1)

Formulation optimization to meet EN 50575 for a use according the latest regulations.

Versions designed to meet the highest requirements in terms of temperature for high reliability usage.

Linkflex HF contributes to low smoke emission cable design as per IEC60754.

Resistance to abrasion makes Linkflex HF an excellent choice for the most demanding cable installation conditions such as conduit, cable trays, stringent bends …

Linkflex HF is offering an excellent flexibility to ensure performance and easiness during network installations.

Crosslinked grades for improving servicing temperature and mechanical properties for a suitable usage in harsh conditions

Resistance to solvents and other chemical resistance against hydrocarbons and oils.

(*) Valid for XLPE insulationcable.

Data sheets on request.

Linkflex HF is particularly adapted for sheathing the whole range of voltage requirement for energy cables, from low to extra high voltage.

O Product compatibile with the application

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS606 |

1.54 |

>10 |

>150 |

27 |

46 |

-25/90 |

DataCom, FO sheating (Eca) |

HFS607 |

1.51 |

>10 |

>125 |

34 |

43 |

-25/90 |

DataCom, FO sheating. Enhancd Fire Performance |

HFS611 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

FTTH ESCR |

HFS613 |

1.58 |

>10 |

>125 |

38 |

44 |

-40/90* |

FTTH ESCR enhanced fire |

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFX003 |

1.49 |

>10 |

>150 |

- |

40 |

-25/90 |

Sheating moisture crosslinkable compound for photovolatic cables |

|

|

|

|

|

|

|

|

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS512 |

1.58 |

>10 |

>150 |

38 |

48 |

-40/90* |

Sheating compound for armored Railway Network |

HFS511 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

Desert grade LSOH armored cables |

HFS513 |

1.58 |

>10 |

>150 |

37 |

52 |

-40/90* |

CPR Desert grade LSOH armored cables |

Linkflex HF range is focused on bulding applications for low and medium voltage applications. With different grades, Hiflex is able to cover standard 300/500V basic levels up to the highest CPR classes and energy applications.

Based on polyolefin matrix, the Linkflex HF series complies with IEC60754-2 standard for low acidity emissions. Behavior during fire exposure has been optimized to allow cables to meet EN 50575 standard classes from Eca up to B2ca with associated features such as low droplet generation.

Mechanical, chemical resistance and climatic characteristics has been optimized to allow high level of flexibility and easiness of use for final users.

A particular care has been taken to optimize the key characteristics for cable processing, to make sure that the total cost for cable manufacturer remains efficient and under control.

The latest compounding processing techniques has been chosen to make sure that product stability and quality are at optimum levels.

In addition, BENVIC's created a dedicated enginnering team with cable compound designers that provides the support to extend and adapt the properties of the Linkflex HF range for specific customer needs.

The Linkflex HF series complements BENVIC's expertise in PVC compounds and reaffirms the company's expertise in productions for the building, construction, electrical and cable industries.all cables manufacturers, and being a long term partner for cable polymers.

Deployment of high speed internet and 5G wireless technology call for range of cable able to meet the application specific requirements and able to offer long life service. Linkflex HF grades are dedicated for based on CPR rated thin layer case.

Benvic compounding know how is a great advantage regarding the formulation of cable where specific features, mission critical, need to be ensured without compromises. Dedicated engineering teams for cable compounds can sustain customer cases for marine, industrial, automotive and transportation applications.

Linkflex HF is using polyolefin matrix which allows low acidity smokes to meet the latest safety requirements.

Linkflex HF does not simply offer compliance with market regulations. Successful cable manufacturers must also demonstrate value-for-money products. This can only happen by focusing on an optimum performance in plastics processing and by minimizing and removing non-quality and non-efficiency costs. Benvic has taken particular care to produce the new Linkflex range at optimum cost.

.

|

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS002 |

>10 |

>150 |

38 |

49 |

-40/90* |

IEC Sheatig 1kV Cable |

HFS002-G |

>10 |

>125 |

38 |

42 |

-40/90* |

BS Sheating 1kV cables |

HFS003 |

>10 |

>150 |

39 |

48 |

-40/90* |

CPR Sheating 1kV Cable |

HFS009 |

>12.5 |

>300 |

- |

- |

-40/90* |

Cables for energy distribution (LV UTILIES) |

HFM001 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV Cable |

|

|

|

|

|

|

|

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

Applicable Standard |

HFI009 |

1.57 |

>10 |

>150 |

40 |

45 |

-25/70 |

LV Insulation H05Z1 & H07Z1 cables Mass insulation (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI011 |

1.54 |

>10 |

>150 |

35 |

48 |

-25/70 |

Insulation H05Z1 & H07Z1 cables Skin layer (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI012 |

1.49 |

>10 |

>150 |

34 |

52 |

-25/70 |

Thermoplastic Insulation for Z1Z1, Z1C4Z1 cables (CPR) |

EN5363-7 TI6 EN5363-7 TI7 |

HFI014 |

1.57 |

>10 |

>125 |

37 |

51 |

-25/70 |

CPR Insulation H05Z1 & H07Z1 cables Mass insulation |

EN5363-7 TI7 |

HFI018 |

1.59 |

>10 |

>125 |

41 |

51 |

-25/70 |

Insulation for 500V & 750V cables. CPR (B2ca) |

EN5363-7 TI7

|

HFM001 |

1.61 |

>10 |

>150 |

38 |

49 |

-40/90* |

Insulation / IEC sheating 1kV cable |

EN5363-7 TI6 EN5363-7 TI7 |

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Building residential |

Public building |

Datacom |

Fiber Optic |

Energy |

Photovoltaic |

Utilities Industrial |

HFS002 |

O |

O |

O |

|

|

|

O |

HFS002-G |

O |

O |

O |

|

|

|

O |

HFS003 |

O |

O |

O |

|

|

|

|

HFS009 |

|

|

|

|

O |

|

|

HFS512 |

O |

O |

O |

|

|

|

|

HFS511 |

|

|

|

|

|

|

O |

HFS513 |

|

|

|

|

|

|

O |

HFS606 |

|

|

O |

O |

|

|

|

HFS607 |

|

|

O |

O |

|

|

|

HFS611 |

|

|

|

O |

|

|

|

HFS613 |

|

|

O |

O |

|

|

|

HFM001 |

O |

O |

O |

O |

O |

O |

O |

HFX003 |

|

|

|

|

|

O |

|

HFI009 |

O |

O |

|

|

|

|

|

HFI011 |

O |

O |

|

|

|

|

O |

HFI012 |

O |

O |

|

|

O |

|

|

HFI014 |

O |

O |

|

|

|

|

|

HFI018 |

O |

O |

|

|

|

|

|

HFM001 |

O |

|

|

|

O |

|

O |

Compliance up to the indicated CPR euroclass associated to right cable design. (1)

Formulation optimization to meet EN 50575 for a use according the latest regulations.

Versions designed to meet the highest requirements in terms of temperature for high reliability usage.

Linkflex HF contributes to low smoke emission cable design as per IEC60754.

Resistance to abrasion makes Linkflex HF an excellent choice for the most demanding cable installation conditions such as conduit, cable trays, stringent bends …

Linkflex HF is offering an excellent flexibility to ensure performance and easiness during network installations.

Crosslinked grades for improving servicing temperature and mechanical properties for a suitable usage in harsh conditions

Resistance to solvents and other chemical resistance against hydrocarbons and oils.

(*) Valid for XLPE insulationcable.

Data sheets on request.

Linkflex HF is particularly adapted for sheathing the whole range of voltage requirement for energy cables, from low to extra high voltage.

O Product compatibile with the application

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS606 |

1.54 |

>10 |

>150 |

27 |

46 |

-25/90 |

DataCom, FO sheating (Eca) |

HFS607 |

1.51 |

>10 |

>125 |

34 |

43 |

-25/90 |

DataCom, FO sheating. Enhancd Fire Performance |

HFS611 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

FTTH ESCR |

HFS613 |

1.58 |

>10 |

>125 |

38 |

44 |

-40/90* |

FTTH ESCR enhanced fire |

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFX003 |

1.49 |

>10 |

>150 |

- |

40 |

-25/90 |

Sheating moisture crosslinkable compound for photovolatic cables |

|

|

|

|

|

|

|

|

(*) Valid for XLPE insulationcable.

Data sheets on request.

|

Density [g/cm3] |

Tensile Strength [Mpa]

|

Elongation [%] |

LOI [%] |

Hardness [shore D] |

Temperature range [°C] |

Specific features |

HFS512 |

1.58 |

>10 |

>150 |

38 |

48 |

-40/90* |

Sheating compound for armored Railway Network |

HFS511 |

1.52 |

>10 |

>150 |

34 |

52 |

-40/90* |

Desert grade LSOH armored cables |

HFS513 |

1.58 |

>10 |

>150 |

37 |

52 |

-40/90* |

CPR Desert grade LSOH armored cables |